BLDC Motor in Electric Vehicles: The Complete 2025 Guide

Introduction: The Pulse of India’s EV Revolution

India is rapidly transitioning towards sustainable mobility, with electric vehicles (EVs) at the center of this green revolution. At the heart of almost every modern EV—whether a nimble two-wheeler zipping through city streets or a family-friendly electric car—lies the BLDC motor. Short for Brushless DC Motor, this technology is quietly powering the shift towards clean, efficient transport.

But what makes BLDC motors the backbone of India’s electric vehicle boom? Why are they preferred over traditional motors, and how do they impact your daily driving experience? This comprehensive guide demystifies the BLDC motor’s role in EVs, explores its benefits and challenges, and offers actionable insights for manufacturers, buyers, and curious enthusiasts alike.

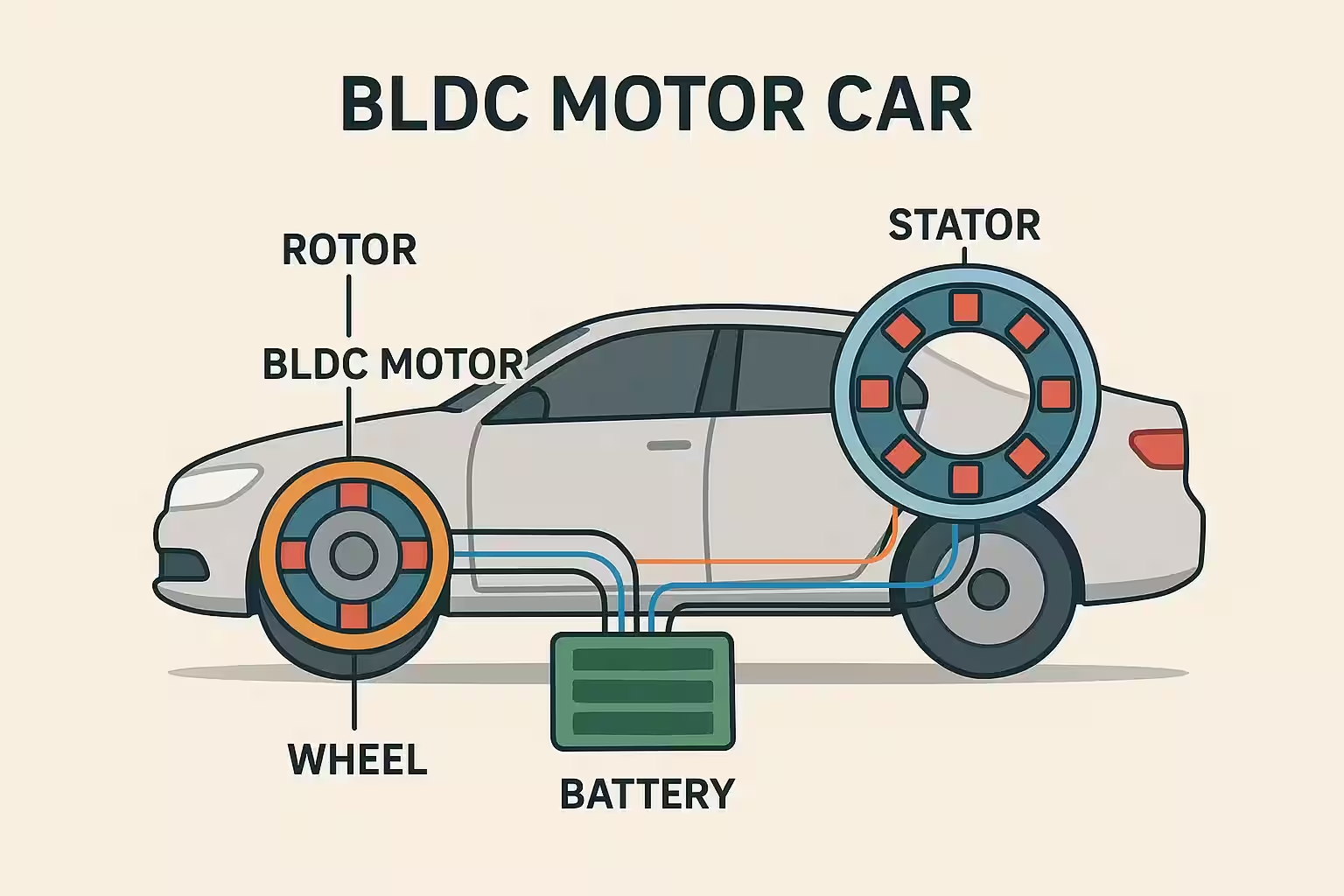

What is a BLDC Motor? An Overview

A BLDC (Brushless Direct Current) motor is an electric motor powered by direct current electricity and controlled electronically rather than by mechanical brushes. Unlike traditional brushed DC motors—where brushes physically switch current to the spinning part (rotor)—the BLDC motor uses electronic controllers to achieve commutation.

Key Components of a BLDC Motor

- Stator: Stationary part with coils.

- Rotor: Rotating part with permanent magnets.

- Electronic Controller: Replaces brushes by managing current flow using sensors or sensorless algorithms.

How Does a BLDC Motor Work?

- The controller sends current to stator windings.

- A magnetic field is generated in sequence.

- The rotor (permanent magnets) follows this rotating field, causing motion.

This design eliminates friction-causing components (like brushes), resulting in higher efficiency and lower maintenance.

Why Are BLDC Motors Popular in Electric Vehicles?

Advantages Over Brushed DC Motors

| Feature | Brushed DC Motor | BLDC Motor |

|---|---|---|

| Efficiency | Moderate | High |

| Maintenance | Frequent (brushes) | Low (no brushes) |

| Lifespan | Limited | Long |

| Noise | Noisy | Quiet |

| Power Density | Lower | Higher |

Real-World Impact

For Indian EV buyers and fleet operators, these advantages translate into:

- Longer battery range per charge

- Reduced maintenance costs

- Quieter urban rides

- More reliable performance in stop-start traffic

Key Facts: BLDC Motors in Indian EVs (2025 Update)

- Over 90% of Indian electric two-wheelers use BLDC motors as of 2024.

- Major Indian EV makers—Ola Electric, Ather Energy, Tata Motors—use high-efficiency BLDC drives.

- Central government policies like FAME II incentivize high-efficiency motors for better range and reliability.

- Advancements such as sensorless control are making BLDC motors more affordable for mass-market vehicles.

Types of BLDC Motors Used in Electric Vehicles

1. Inner Rotor vs. Outer Rotor Designs

- Inner Rotor: Rotating core inside stationary windings; common in e-cars for higher torque needs.

- Outer Rotor: Magnets rotate outside stationary windings; often used in e-bikes/scooters for compactness.

2. Inrunner vs. Outrunner Applications

- Inrunner: Faster speed, lower torque—ideal for cars, buses.

- Outrunner: Higher torque at lower speeds—favoured in scooters and e-rickshaws.

How Do You Choose the Right BLDC Motor for Your EV?

Consider These Factors:

- Power Rating (kW): Match with vehicle weight and desired acceleration.

- Voltage: Higher voltage can mean more power but needs compatible batteries.

- Torque Requirements: City commuting vs. hilly terrain needs differ.

- Cooling Needs: Heavier vehicles may require advanced cooling solutions.

- Controller Compatibility: Ensure smart integration with your vehicle’s electronics.

Example Table: Typical Motor Ratings

| Vehicle Type | Power Range (kW) | Voltage |

|---|---|---|

| E-Bike/Scooter | 0.25 – 3 | 24–72 V |

| E-Car | 10 – 50 | 72–400 V |

| E-Bus | 80 – 250 | 400–600 V |

Eligibility & Standards: Are All EVs Using BLDC Motors?

While most modern Indian EVs use BLDC motors due to their efficiency, it is not a legal requirement—but it’s strongly encouraged by industry standards and government incentives.

Relevant Standards & Certifications:

- AIS 138: Specifies performance and safety requirements for traction motors used in EVs sold in India.

- FAME II Incentives: Extra subsidies for vehicles using high-efficiency motors like BLDCs.

Who Should Use Them?

- Manufacturers aiming for FAME subsidies or exports must comply with these standards.

- Fleet operators seeking low total cost of ownership benefit most from switching to BLDC-powered fleets.

Benefits of Using a BLDC Motor in an Electric Vehicle

For End Users / Owners

- Extended Range: Up to 15–20% improved efficiency over brushed types means fewer charging stops.

- Lower Maintenance: No brushes = less wear-and-tear; annual servicing suffices.

- Longer Lifespan: Designed to last over a decade with minimal issues.

- Smooth Driving Experience: Instant torque delivery makes overtaking or hill-climbing effortless.

- Quieter Operation: Ideal for urban commutes or silent zones.

For Manufacturers & Fleets

- Compliance with latest government standards

- Enhanced customer satisfaction due to reliability

- Scope for advanced features like regenerative braking

- Better warranty claims record due to fewer breakdowns

The Process: How Is a BLDC Motor Integrated into an Electric Vehicle?

Step-by-Step Integration Process

-

Requirement Analysis

- Define torque, speed, voltage needs based on vehicle type and application.

-

Motor Selection

- Choose inner/outer rotor type; select power rating compatible with battery pack.

-

Controller Integration

- Program electronic controller for precise speed/torque management; integrate safety features like thermal cutoffs.

-

System Testing

- Rigorous bench-testing followed by road trials under real-world conditions.

-

Certification & Compliance

- Submit prototypes for AIS certification; ensure FAME eligibility if targeting incentives.

-

Production Rollout

- Begin mass production after final validations; maintain strict quality control.

Expert Insights on Future Trends (2025)

Industry leaders point out several trends that will shape how BLDC motors evolve within India’s electric mobility ecosystem:

Dr Rakesh Sharma (EV Technology Consultant):

“Next-generation BLDC drives will offer integrated IoT monitoring—allowing predictive maintenance alerts directly on your smartphone.”

Ms Priya Dey (EV Manufacturing Specialist):

“The cost gap between traditional induction motors and premium-grade BLDC units is narrowing fast due to local component sourcing.”

Key Upcoming Trends:

- Shift towards sensorless control algorithms to cut costs further

- Integration with AI-based battery management systems

- Development of ultra-lightweight magnet materials for higher power density

- Wider adoption beyond two-wheelers—into buses and commercial fleets

- Focus on fully recyclable materials due to new sustainability mandates

Practical Advice & Tips For Buyers And Owners

For Prospective Buyers:

- Ask about the motor type before purchasing any EV—insist on certified high-efficiency units.

- Compare rated efficiency figures (look for >85%).

- Check warranty terms specifically covering the traction motor and controller unit.

For Current Owners:

- Schedule periodic inspections even though maintenance needs are low—especially check cooling systems before summer months.

- Use only certified service centers familiar with your vehicle’s specific controller software/hardware integration.

- Stay updated about firmware upgrades offered by manufacturers that may improve driveability or add features via over-the-air updates.

For Fleet Managers:

- Track long-term total cost per km—a good quality BLDC system will typically reduce operational costs by up to 30% compared to legacy systems over five years.

- Prioritize brands offering remote diagnostics or telematics integration alongside basic motor warranty coverage.

Comparison: Other Common Motor Types vs BLDC Motors in EVs

| Parameter | Brushed DC | Induction AC | Permanent Magnet Synchronous (PMSM) | Brushless DC (BLDC) |

|---|---|---|---|---|

| Efficiency | Low | Medium | High | High |

| Maintenance | High | Medium | Low | Very Low |

| Torque Delivery | Moderate | Smooth | Very Smooth | Rapid |

| Cost | Low | Medium | High | Medium |

| Application | Rarely used now | Buses/High Power | Premium Cars | Most Indian EVs |

Note: PMSM motors are closely related to BLDC but differ mainly in rotor construction and control complexity; both offer high efficiency but PMSM may edge ahead at very high power levels (luxury cars).

Use Cases & Success Stories from India

- Ather Energy’s scooters use custom-designed outer rotor BLDC motors enabling rapid acceleration while keeping weight low—a key factor behind their popularity among young urban riders.

- Tata Nexon EV employs robust inner rotor types paired with advanced controllers for highway-capable performance without sacrificing city driveability—a reason why it leads sales charts among family e-cars under Rs 20 lakh.

- Smart e-rickshaws across Delhi NCR adopted locally sourced sensorless BLDC drives post-FAME II policy changes, helping operators cut downtime by half compared to older induction-motor models.

Frequently Asked Questions (FAQ)

Q1: Are all electric vehicles equipped with a BLDC motor?

No—not all EVs use BLDC motors, but most modern two-wheelers and many passenger cars do because of their efficiency advantages over older technologies like brushed DC or induction motors.

Q2: How long does a typical automotive-grade BLDC motor last?

With proper care, such motors can easily last over ten years or more than one lakh kilometers under normal usage conditions.

Q3: Can I retrofit my old petrol scooter/bike with a BLDC motor kit?

Yes, several vendors offer certified retrofit kits using compact outer rotor-type BLDC units suitable for popular scooter/bike models—but always ensure compliance with local RTO regulations before conversion.

Q4: Are there any disadvantages to using a BLDC motor?

Initial purchase cost can be slightly higher than some alternatives; also, sophisticated electronic controllers require skilled servicing if issues arise—however, these are offset by savings on fuel and maintenance over time.

Q5: Do all charging stations support vehicles powered by a BLDC motor?

Yes—the charging standard depends on your vehicle’s battery system rather than the type of traction motor used.

Action-Oriented Summary & Takeaway

The rise of electric mobility across India would not be possible without innovations like the brushless DC (BLDC) motor—a technology that delivers unmatched efficiency, longevity, and quiet operation vital for our cities’ future health and productivity.

Whether you’re buying your first e-scooter or planning an entire fleet upgrade, understanding how—and why—BLDC drives work puts you ahead as an informed consumer or operator in this fast-evolving market landscape of 2025.

Always prioritize certified manufacturers who invest in advanced motor technologies aligned with government standards—you’ll enjoy better range today while supporting India’s transition toward smarter, greener mobility tomorrow.

Sources

- Ministry of Heavy Industries – FAME India Scheme Guidelines

https://heavyindustries.gov.in/user_index.aspx?id=11&lid=41&lang=1 - Automotive Research Association of India – AIS Standards

https://www.araiindia.com/standards.php - Society of Manufacturers of Electric Vehicles – Technical Resources

https://www.smev.in/ - Ather Energy Technical Blog

https://blog.atherenergy.com/ - Tata Motors Electric Mobility Portal

https://ev.tatamotors.com/ - IEEE Spectrum – “How Brushless DC Motors Work”

https://spectrum.ieee.org/how-brushless-dc-motors-work